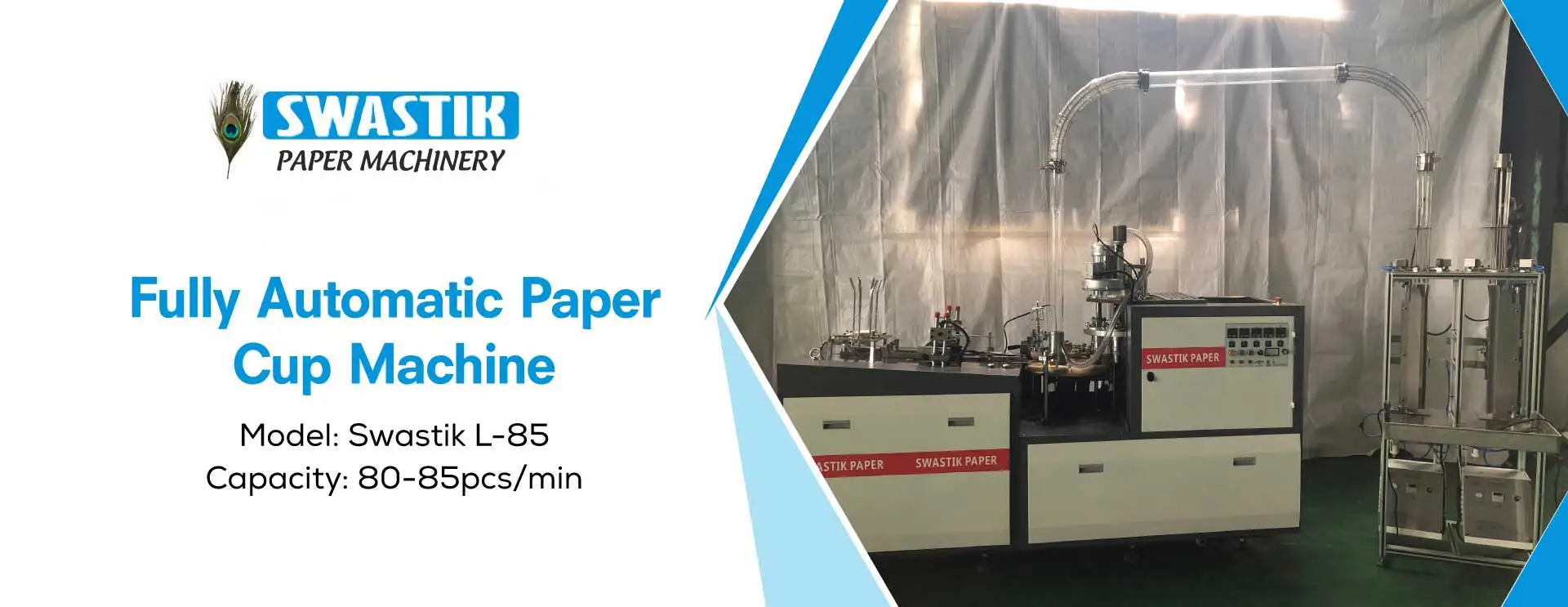

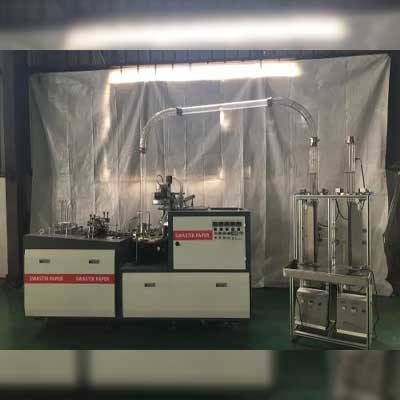

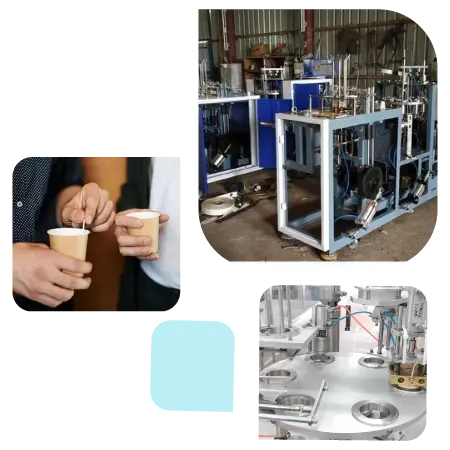

Best Quality And High Speed Machines

Over Thousands Of People Have Chosen Swastik As Their Machinery Partner

Our manufacturer understands that your cup-making needs are unique. That's why we offer customization option.

Rated As Number One And Most Trusted Paper Machines Supplier All Over The Country