- Home

- Company Profile

- Our Products

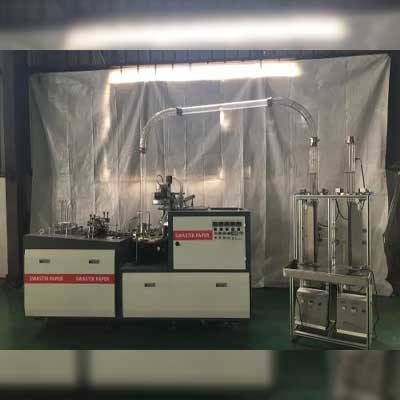

- Paper Cup Making Machine

- Disposable Glass Making Machine

- Tea Cup Making Machine

- Ripple Cup Making Machine

- High Speed Automatic Paper Bowl Plate Machine

- Paper Lid Making Machine

- Paper Container Making Machine

- Tissue Paper Making Machine

- Aluminum Foil Container Making Machine

- Paper Cup Raw Material Making Machine

- High Speed Paper Cup Glass Making Machine

- Paper Glass Making Machine

- Flexo Printing Machine

- Paper Cup Blanks

- Paper Cup Bottom

- Muffin Cup Making Machine

- Heavy Duty Die Punching Machine

- Double Wall Paper Cup Making Machine

- LDPE Extrusion Machine

- Disposable Cup Making Machine

- Blogs

- Our Story

- Contact Us